How to Properly Lubricate Your Planetary Gears

One of the most important things you can do for your planetary gear systems to keep them working exactly how you want and need them to is to make sure you are properly lubricating them. The amount and even the type of lubrication you use for your gear depends on how you are using your gears and the size you are using.

Smaller Gears

Many of our smaller planetary gears come pre-lubricated with the proper amount of grease. While others are just lightly oiled. The amount will vary depending on your application and how you are housing those gears as well.

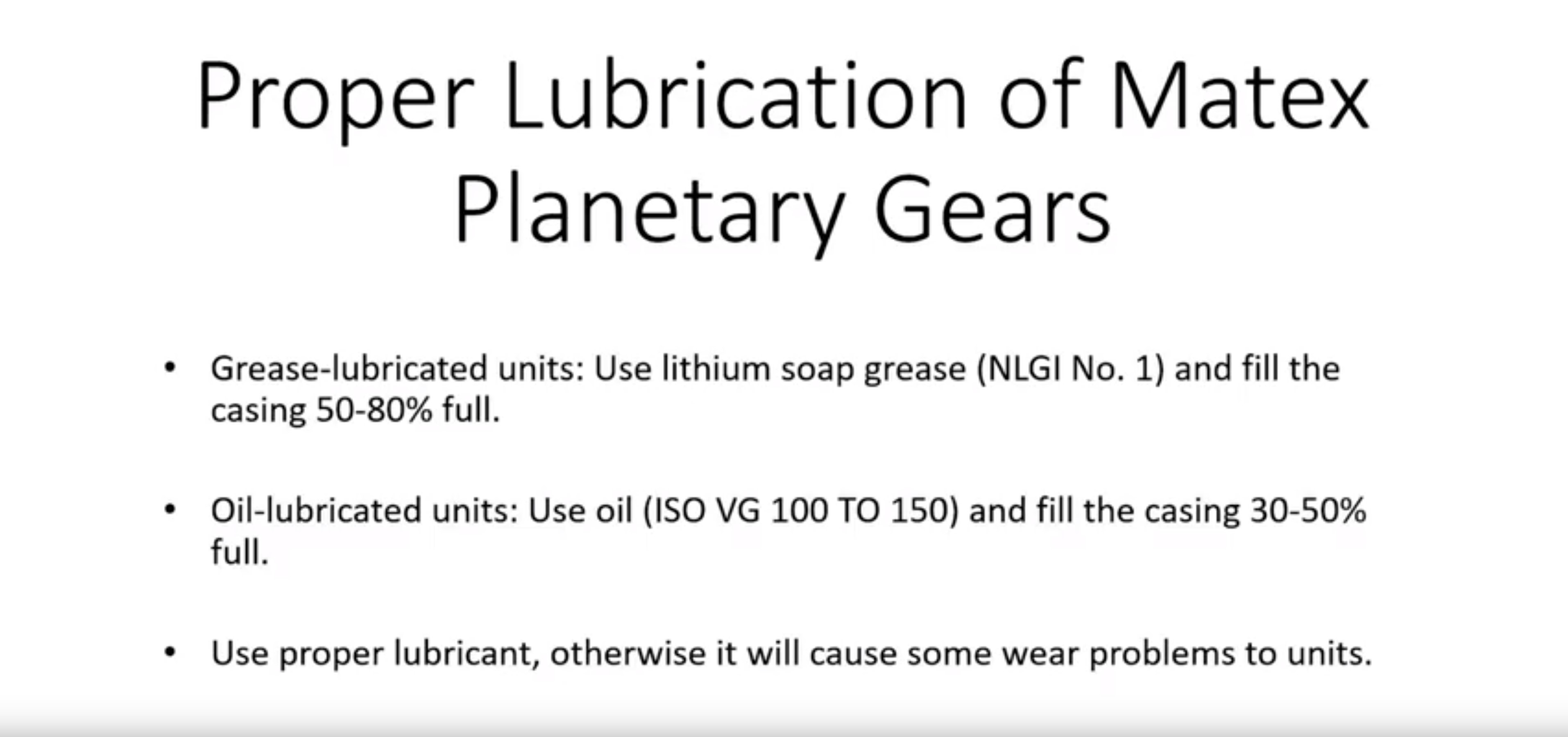

In a grease lubricated unit, we suggest you follow the manufacturer's recommendation of using a lithium soap grease, NLGI number 1 (this is a Japanese industrial standard), and fill the casing 50 to 80% full.

Larger Gears

Larger planetary gears are often lubricated with oil instead of grease. The manufacturer suggests using an ISO VG between 100 and 150, that's the weight of the oil.

Improper Lubrication

It is essential to keep your planetary gears properly lubricated otherwise some wear issues may arise in your unit. Generally, heat and friction are your big problems when you're running a gear especially if you're running it at a high RPM (rotation per minute). This is why you may want to even design your housing to help the heat sink away from the gear.

Moreover, we often suggest that if you have a gear that could be running a little bit on the hot side, use a synthetic oil. Synthetic oil is the best application for hot gears. In this type of situation, you will want to fill the casing 30 to 50 percent full.

Overall, it is important to be knowledgeable about how you are using your gear, how you're housing it, and how to properly lubricate your planetary gears. Improper lubrication can really wear the life and usage of your gears. To find out if you are taking care of your planetary gears, contact us, and we can give you the information you need!

View Cart []

View Cart []